Toggle main menu visibility. Lake Mary, FL, January 12, 2016 – FARO Technologies, Inc. (NASDAQ: FARO), announces highly-adaptable 3D imager arrays that promise to drive automated industrial manufacturing metrology processes to the next level. The new FARO Cobalt 3D Imager is equipped with dedicated on-board processors – an industry first.

The smart sensor allows unique multi-imager array configurations enabling industrial manufacturers to significantly improve productivity and operations in a way never before possible. An unlimited number of 3D imagers can be placed in array configurations virtually anywhere in a manufacturing process – all scanning simultaneously and controlled by a single computer. Ideal for integration within the production environment, Cobalt can also be installed in more conventional ways, such as in conjunction with a rotary table, robot, or industrial inspection cell.

Combining blue light projection, stereo cameras and powerful on-board processing, Cobalt captures and processes millions of 3D data points in seconds. With high resolution, automatic exposure and high dynamic range, Cobalt expertly handles complex parts with fine details, varying colors, textures and reflectivity. Cobalt delivers fast and consistent measurements, independent of the operator, for quality inspection and reverse engineering applications on parts, assemblies, and tools. “The FARO Cobalt 3D Imager delivers reliable and accurate 3D scan data within an automated workflow. With no restrictions on the number of sensors in an array, the sky is the limit for improving inspection cycle time, making it an exciting new product that enhances the FARO portfolio for in-process or near-process inspection,” stated Dr.

Simon Raab, FARO’s President and CEO. “The price and capabilities of Cobalt make it a cost-effective, versatile, and convenient tool that delivers a rapid return on investment for customers in a variety of metrology and product design applications.” Dr. Raab added, “We are particularly proud of Cobalt’s patent-pending on-board processing feature, which ultimately helps simplify the integration of the sensor into advanced production environments.

Coupled with FARO’s CAM2 ® Measure 10 software, an unlimited number of Cobalt sensors can simultaneously capture large surface areas or complex assemblies. The configurable field of view, intelligent on-board point cloud processing and resolution can adapt to multiple measurement needs. Our analysis shows that for dedicated inspections of large products or assemblies, a fixed multiple imager array of Cobalt sensors will be faster, more easily integrated, more affordable, more accurate and easier to maintain than purchasing the robot-based imager or laser line systems currently on the market. Yet, Cobalt can also outperform as a robot-based system with its high resolution and data processing speeds in combination with its low profile and light weight.” The FARO Cobalt 3D Imager is designed for quick and easy integration onto the production floor, and seamlessly connects with the full-featured FARO CAM2 Measure 10 metrology software. This press release contains forward-looking statements within the meaning of the Private Securities Litigation Reform Act of 1995 that are subject to risks and uncertainties, such as statements about demand for and customer acceptance of FARO’s products, and FARO’s product development and product launches. Statements that are not historical facts or that describe the Company’s plans, objectives, projections, expectations, assumptions, strategies, or goals are forward-looking statements. In addition, words such as ”is,” “will,” “promise,” “can,” “deliver” and similar expressions or discussions of FARO’s plans or other intentions identify forward-looking statements.

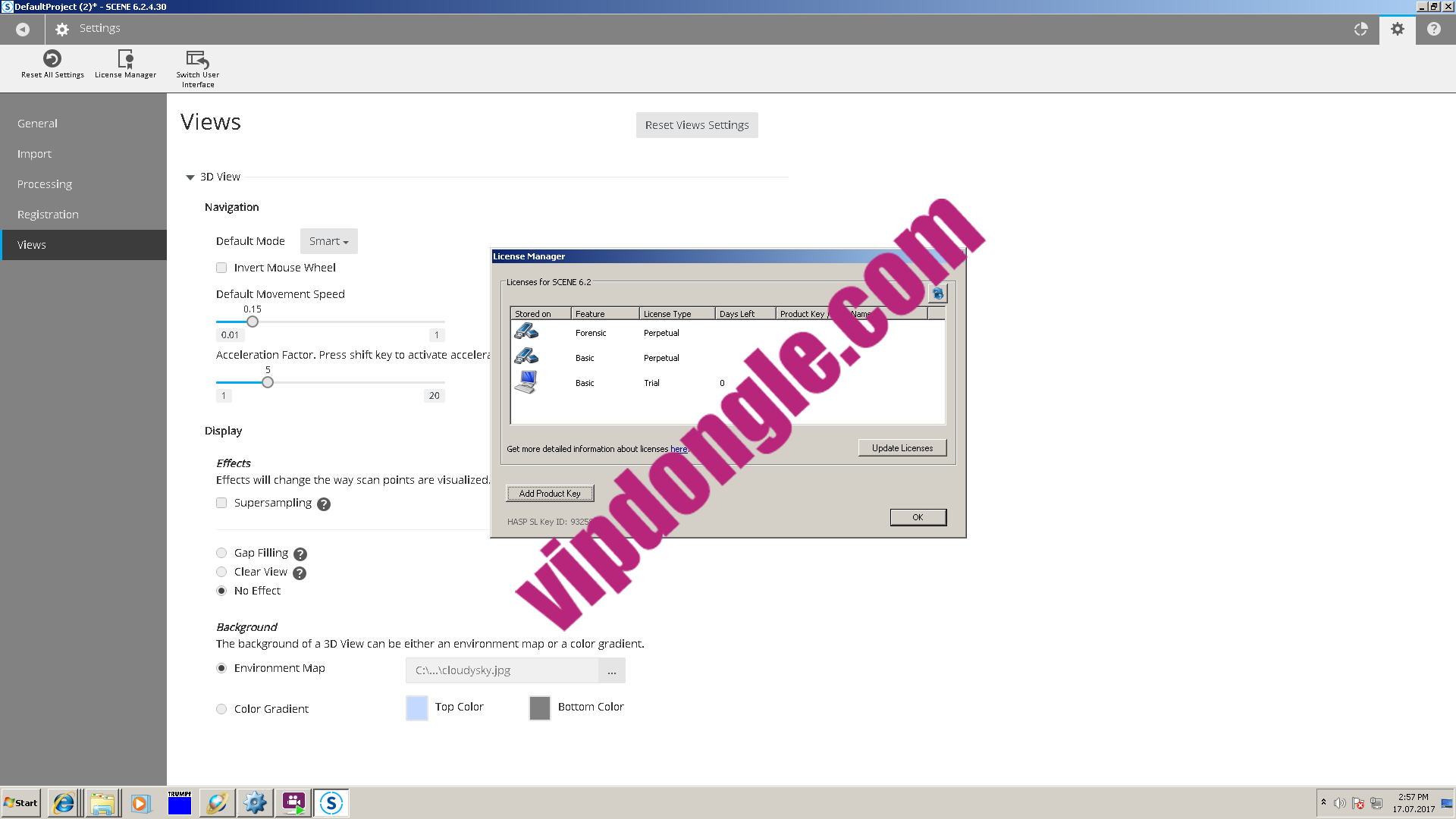

Faro Cam2 Measure 10 Training

Forward-looking statements are not guarantees of future performance and are subject to various known and unknown risks, uncertainties, and other factors that may cause actual results, performances, or achievements to differ materially from future results, performances, or achievements expressed or implied by such forward-looking statements. Consequently, undue reliance should not be placed on these forward-looking statements. Lake Mary, FL, September 19, 2017 – FARO ® (NASDAQ: FARO), the world’s most trusted source for 3D measurement and imaging solutions for factory metrology, construction BIM/CIM, product design, public safety forensics, and 3D solutions applications, announces the availability of the FARO ® Visual Inspect TM product family.

This innovative platform enables large, complex 3D CAD (computer-aided design) data to be transferred to an iPad and then used for mobile visualization and comparison to real world conditions. To watch an overview video, go to. This enables real time, actionable manufacturing insight through earlier stage error detection in the production, construction or design processes. For more information, go to. Visual Inspect TM is a true next generation solution as it moves 3D CAD viewing away from the traditional desktop PC to a mobile “in hand, on demand” solution. The 3D CAD data is stored locally on the iPad through an innovative, compressed, mobile format which provides an exceptional degree of flexibility and mobility that together drive increased productivity.

The end user is able to document problems and errors with text and images and then easily export both into a Microsoft Excel office document. The Visual Inspect TM product family offers two exceptional value options. Visual Inspect TM: enables intuitive mobile viewing, verification and documentation of complex 3D data. Visual Inspect AR TM: enables complex 3D data to be overlaid and compared to actual data in real time The integrated iPad camera supports Visual Inspect AR TM as a more cost effective alternative to other Augmented Reality (AR) products that require expensive cameras. The Visual Inspect TM product family can be ready for use via a simple three step process that includes first downloading the iPad application from the Apple Apps store, calibrating the iPad and then activating the application with the calibration file. “We are thrilled to follow up our purchase of mwf-technology in December 2016 with the integration of its innovative technology into the FARO product portfolio,” stated Simon Raab, Ph.D., FARO’s President and CEO.

“We are creating a new paradigm that enables our customers to move beyond doing it the right way most of the time to doing it the best way all the time.” The Visual Inspect TM family is available now for quoting and ordering. T his press release contains forward-looking statements within the meaning of the Private Securities Litigation Reform Act of 1995 that are subject to risks and uncertainties, such as statements about demand for and customer acceptance of FARO’s products, and FARO’s product development and product launches. Statements that are not historical facts or that describe the Company’s plans, objectives, projections, expectations, assumptions, strategies, or goals are forward-looking statements. In addition, words such as “is,” “will” and similar expressions or discussions of FARO’s plans or other intentions identify forward-looking statements.

Forward-looking statements are not guarantees of future performance and are subject to various known and unknown risks, uncertainties, and other factors that may cause actual results, performances, or achievements to differ materially from future results, performances, or achievements expressed or implied by such forward-looking statements. Consequently, undue reliance should not be placed on these forward-looking statements.

Cam2 Measure 10.7

The training I received with Jeff and his team was unparalleled to any I have received before. Things I had been struggling with or did not quite understand were presented in a manner that I could completely wrap my mind around and could then explain to others. The hands on approach that they used helped me grasp the machine and software workings and capabilities. I highly recommend Diverse Dimensions to not only new users but also veteran users. Quality Engineering C & S Machine & Manufacturing Corp.